OIL AND GAS HOSE

High Performing Oil and Gas Hose Assemblies.

Abdex has supplied the oil and gas industry for more than 20 years with hose assemblies, fittings and valves. Covering a vast array of applications including High Pressure Fluid Injection, Cementing, BOP Control Lines, Jumpers, Well Intervention, Abandonment, and Pipeline Testing. The oil and gas sector demands the very best in reliability, durability and consistent high performance to which Abdex provides specialised solutions to meet these demands.

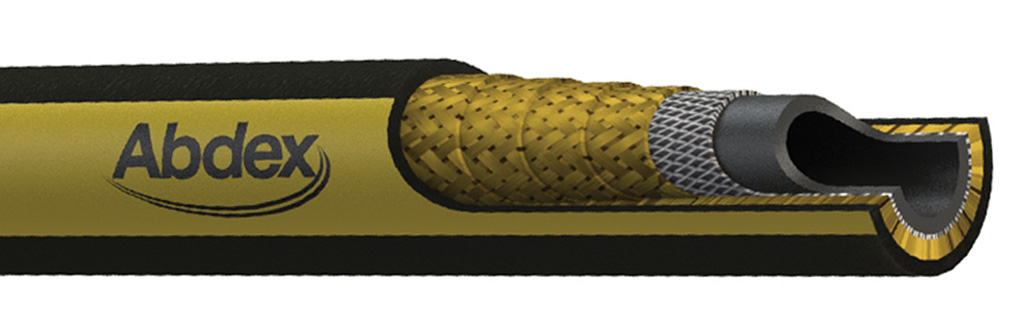

Abdex is the only certified company in Australasia to supply the complete Black Eagle range of thermoplastic hoses. As well as being Australia’s only certified API Q1 & 7K manufacturer. This showcases our dedication to meet and exceed strict industry standards.

Black Eagle

Black Eagle Oilfield service hose is up to 30% lighter than R13 rubber hose and 70% lighter than iron pipe.

BOP & Hot Line

All Fire Armor BOP hose assemblies are tested and approved by Lloyd's Register, and comply with American Petroleum Industry API16D guidelines.

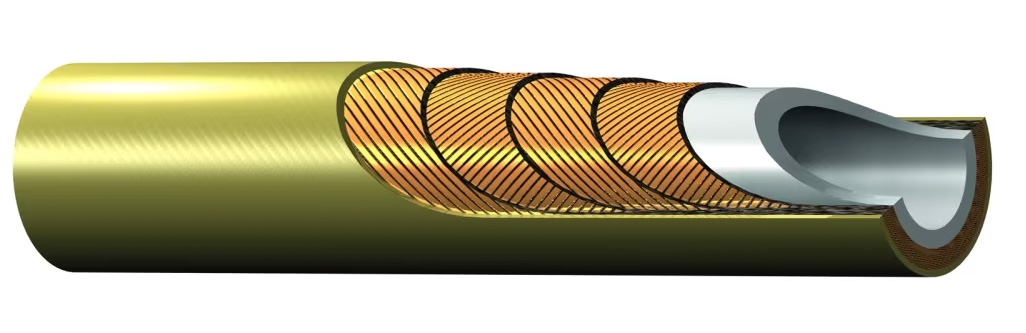

Wire Reinforced

Long length subsea umbilical hose suitable for deep sea applications requiring very high pressure and high collapse strength.

Aramid Braided

Long length hose and hose umbilicals requiring lightweight construction. Weighing up to 20% less than comparable rubber hoses.

Chemical Injection

Ideal for offshore / onshore transfer applications involving suction and discharge services for the transfer of water, petroleum based fluids, chemicals and abrasive materials.

Drilling

Our scope of specialised drilling and industrial hoses include certified API 7K and 16D hose assemblies, that cater for all sectors of the drilling industry.

Umbilicals & Jumper Hose Assemblies

Abdex umbilicals are designed for use in the offshore industry to offer a combination of long service life, chemical resistance, flexibility and lightweight construction. As Abdex is an independent supplier we can can use products to suit specific customer requirements.

Industrial

Abdex has manufactured a wide range of industrial hose assemblies for the past 50 years. We work closely with leading manufacturers from around the world, such as Contitech, Gates, Parker and others.