Description

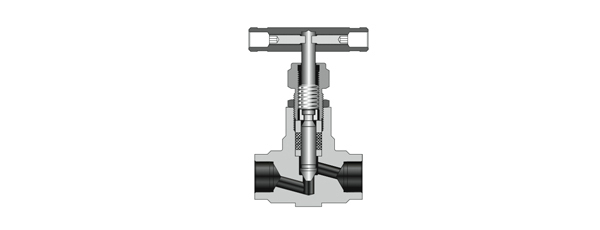

Needle Valves

• The non-rotating stem eliminates galling between the seat and tip, and reducing the friction of sealed packing. Effectively improving the service life of the valve and valve packing.

• Intermittent packing system designed to effectively reduce the cold flow of valve packingand the valve operating torque. While using the system media for the use of valve packing.

• Packing mounted on the bottom of the stem transmission thread designed to achieve the isolation of transmission thread lubricating material and system medium to prevent transmission thread lubricating substance contamination of the media on the system.

• Threaded operating torque transmitted using online extrusion and roll forming process, effectively improves the strength and precision of the threads. To provide strong protection for operating torque for the screw to pass long-term, stable and reliable torque transmission.

• Different body materials and structure selection, a variety of colours and forms of the handle and optional panel mounting structure to achieve different requirements and different application occasions.