Description

P320 Modular Test Bench – Technical Data

| P 320 | |

|---|---|

| Test pressure | 150 - 1,500 bar / 2,175 - 21,750 psi |

| Control | Manual |

| Drive | Diaphragm pump + intensifier |

| Flow rate (effectively) | 12.5 l/min |

| Tank dimensions closed (L x W x H) mm (Zoll) | External: 2,270 x 1,420 x 2,525 (63.3" x 49.6" x 83.8") Internal: 1,607 x 1,260 x 2,130 (89.4" x 55.9" x 99.4") |

| Aggregate dimensions | – (integrated) |

| Reservoir capacity | 150 l |

| Colour | RAL 5012 blue/RAL 7021 grey |

| Weight of tank | P 350 Container: 650 kg |

| Weight of power unit | - |

| Noise level | 75 dBA |

| Max. hose length | depending on Ø, several meters on coil possible |

| Test medium | Water-oil emulsion EM-CO 18kg |

Innovation and quality

- 120 hoses per hour testable

- 4 parallel test pieces per chamber

- Mirror symmetrical connection of two test chambers

- Easier workflow thanks to chambers that can be used autonomously (loading and testing possible at the same time)

- Quick clamping system for holding up to four hoses simultaneously incl. variable settings

- Interior lighting, height adjustable machine feet and high quality internal gear pump.

- Change between automatic and manual setup mode

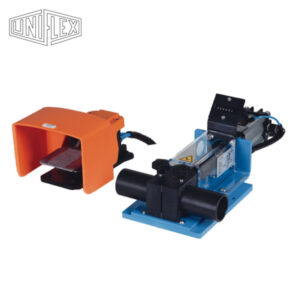

- Separately exchangeable and flexibly positionable unit (incl. 2 m connecting hoses)

- Max. Hose length up to 2,500 mm

Safety and CE conformity

- Automatic closing of the test chamber

- Large inspection windows made of Makrolon®

- Display for bubble-free flooding in the unit

- Individually customizable inspection or test protocols (printable and storable)