Description

Uniflex HM200, HM 200 Ecoline – Technical Data

| HM 200 | HM 200 Ecoline | |

|---|---|---|

| Crimp force (kN/Ton) | 1,300/130 | 1,300/130 |

| No grease 20% less friction | ✓ | ✓ |

| Control | Control A | Control A |

| SAE R 12/4SP* 1 piece fitting | 1 1/2" | 1 1/2" |

| SAE R 15/4SH* 2 piece fitting | 1" | 1" |

| SAE R 12/4SP* 2 piece fitting | 1 1/4" | 1 1/4" |

| Industrial | 2" | 2" |

| 90° Elbows | 1 1/2" | 1 1/2" |

| Max. Crimp range (mm/inch) | 70 / 2.76 | 70 / 2.76 |

| Opening (mm/inch) | +30 / +1.18 | +30 / +1.18 |

| Opening without dies (mm/inch) | 100 / 3.94 | 100 / 3.94 |

| Master dies length (mm/inch) | 75 / 2.95 | 75 / 2.95 |

| Speed (mm/sec) Close Crimp Open | 3.5 3.5 5.9 | 3.5 3.5 5.9 |

| Noise level | 69 dBA | 69 dBA |

| Drive | 3 kW 3 VAC | 3 kW 3 VAC |

| Oil | 40 l | 40 l (DC 4 l) |

| L x W x H (mm) | 800 x 530 x 630 | 420 x 535 x 520 |

| Power Unit L x W x H (mm) | - | 300 x 450 x 560 |

| Weight | 140 kg | 92 kg (without power unit), 130 kg (with die package) |

| Options | ||

| 12 VDC/24 VDC | - | ✓ |

| 1 VAC | ✓ | 2.2 kW |

| Control C.2/IPC | ✓ | – |

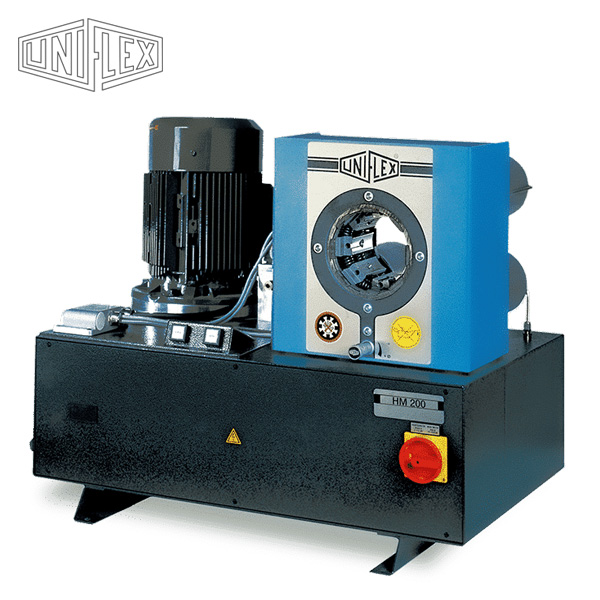

The Uniflex HM200 is a unrivaled classic hose press in the 1 ¼” range offers an unbeatable benchmark for quality and economy due to its narrow innovative design, high user-friendliness, versatility, and long service life.

Their compact design allows ergonomic work in the workshop. The use of the solid base dies enables the pressing of all types of valves and the proven lubrication-free slide-bearing technology reduces maintenance costs.

Variations

HM 200 DC or

HM 200 Ecoline variant

Optional Extras